A complete guide to soft pack battery assembly, a must-read for researchers

A complete analysis of lithium battery internal resistance, understand the core parameters in one article!

Practical EIS data fitting, a must-have skill for battery professionals!

Introduction to lithium battery production process, process flow, principle, formula, and parameters

Introduction to lithium battery production process, process flow, principle, formula, and parameters

Lithium battery principle, formula and process flow

Lithium battery principle, formula and process flow

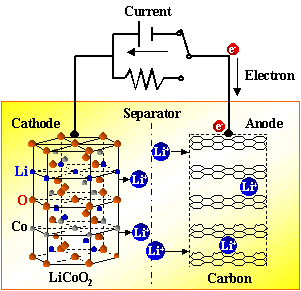

Lithium-ion battery is a secondary battery (rechargeable battery) that mainly relies on the intercalation and deintercalation of Li+ between two electrodes. With the continuous development of downstream industries such as new energy vehicles, the production scale of lithium-ion batteries is expanding. This article takes lithium cobalt oxide as an example to comprehensively explain the principle, formula and process flow of lithium-ion batteries, the performance and testing of lithium batteries, production precautions and design principles.

1. The principle, formula and process flow of lithium-ion batteries;

1. Working Principle

1. Positive electrode structure

LiCoO2 + conductive agent + binder (PVDF) + current collector (aluminum foil)

2. Negative electrode structure

Graphite + Conductive agent + Thickener (CMC) + Binder (SBR) + Current collector (Copper foil)

The commercialization of all-solid-state battery production

Lithium-ion Full Cell Manufacturing Process Training--Soft-Pack Battery Formation - Part 2

1. Key Factors Influencing Formation: Mechanism

Lithium-ion Full Cell Manufacturing Process Training--Soft-Pack Cell Formation - Part One

1. Basic Concepts of Formation

1.1. What is Formation?

l Formation refers to the process of activating the cathode and anode materials inside a battery after it has been fully rested following electrolyte injection. This activation is achieved through a specific charging and discharging cycle, which also leads to the formation of a SEI (Solid Electrolyte Interphase) film on the surface of the active materials. The SEI film helps to improve the overall performance of the battery in terms of charging and discharging, self-discharge, and storage capabilities.

Lithium-ion Full Battery Manufacturing Process Training--Coating

1.Coating Basics

Purpose: To uniformly coat a fluid slurry onto the surface of a metal foil, dry it, and produce a battery electrode

Principle: The coating roller rotates to carry the slurry, and the amount of slurry transferred is adjusted by adjusting the gap between the doctor blade and the roller. The relative rotation of the back roller and the coating roller is used to transfer the slurry onto the substrate. Subsequently, the solvent in the slurry is evaporated through drying and heating, causing the solid matter to adhere to the substrate.

Lithium-ion Full Battery Manufacturing Process Training--Coating 2

1.Electrode Shedding

Negative electrodes are prone to powder shedding

Main reason:

1.Formula issues,insufficient bonding strength leading to material loss

2.Excessive baking temperature,rapid solvent evaporation resulting in SBR

bleeding.Insufficient adhesive between the material and the current collector leading to material loss

Lithium-ion Full Battery Manufacturing Process Training--Coating 3

1.Coating Basics

Purpose:To uniformly coat a fluid slurry onto the surface of a metal foil, dry it, and produce a battery electrode

Principle:The coating roller rotates to carry the slurry, and the amount of slurry transferred is adjusted by adjusting the gap between the blade and the roller. The relative rotation of the back roller and the coating roller is used to transfer the slurry onto the substrate. Subsequently, the solvent in the slurry is evaporated through drying and heating, causing the solid matter to adhere to the substrate.

Lithium-ion Full Cell Manufacturing Process

1.The function of adhesives

Cathode and anode slurries:

Provide viscosity to ensure that particles in the slurry do not easily settle and maintain sslurry stability

Provide viscosity for good fluidity

Provide viscosity to facilitate effective dispersion of materials

Lithium-ion Full Cell Manufacturing Process Training--Soft-Pack Battery Cell Encapsulation

1.Baking

1.1.The main purpose of baking is to remove moisture from the bare cell

H2O can cause the decomposition of LiPF6, leading to an increase in HF levels:

H2O can react with organic solvents in the electrolyte to produce alcohol and CO2, for example:

During the formation process, H2O can decompose, producing H2, consuming lithium ions,

reducing the initial efficiency and capacity of the battery, and damaging the battery interface.

Lithium-ion Full Cell Manufacturing Process Training--Baking and electrolyte injection

1.Rolling Principle

Roll pressing is a process that utilizes a roll press machine (as shown in Figure 1,the roll press machine used in the industry consists of three core components: a pair of rollers, an unwinding device, and a rewinding device) to compress the thickness of the electrode (as shown in Figure 1). This compression increases the compaction density of the electrode coating, reduces the thickness of the electrode, and ultimately enhances the energy density of the battery.

Lithium-ion Full Battery Manufacturing Process Training--Rolling

1.Process Flow

The main components of a lithium battery include a positive electrode with an active material typically being lithium cobalt oxide, a separator made of PP or PE composite membrane, a negative electrode with carbon as the active material, organic electrolyte, and a battery case made of aluminum-plastic composite film. The manufacturing process involves slurry preparation, film coating, assembly, and formation. In recent years, electronic products have become increasingly thinner and lighter, with faster charging speeds and reduced space, resulting in higher demands for the energy density of lithium batteries. Lithium batteries need to be continuously updated and improved to meet these demands, further trending towards smaller, lighter, and thinner batteries. The related topics of lithium batteries have always been a hot research focus. Adopting suitable materials and cell manufacturing processes can improve battery performance. For specific materials and processes, please consult Canrd!

Lithium-ion Full Cell Manufacturing Process Training--Summary of Processes

1.Role and Selection Criteria of Separators

1.1.Role of Separator

1) The separator is an important component of lithium-ion batteries.

2) Electronic insulation and ionic conductivity.

Introduction and Synthesis of Lithium Ion Batteries Negative Material

Introduction and Synthesis of Lithium Ion Batteries Negative Material At present, the negative materials used in lithium-ion batteries are...

-

Effects of Conductive Agents and Binders on Compression and Compactability of NCM Powders In the field of energy development, lithium-ion b...

-

Determined to win ‖ Sun Jie's team from Tianjin University: Micro-multifunctional additives significantly improve the ultra-high voltage...

-

Single-sided pole piece manufacturing method This issue introduces the production process of single-sided pole pieces to help you obtain s...

-

The "Three Musketeers" of Lithium Batteries: Lithium Battery Packaging Film, Lithium Battery Separator and Battery Cell Blue Film ...

-

First author: Meng Li Corresponding author: Boryann Liaw Corresponding Unit: Idaho National Laboratory, USA Achievements at a Glance This ...

-

Interfacial friction makes the vertical structure of lithium metal batteries summary A practical high-energy-density lithium metal battery r...

-

Lithium cobalt oxide is the first commercialized cathode material for lithium-ion batteries. Its theoretical gram capacity after complete de...