Overview of Lithium - Ion Battery Binders

Binders, often grouped with conductive agents and additives as "auxiliary materials" in lithium - ion battery production, are crucial and indispensable materials. Their main function is to adhere active materials and conductive agents to current collectors, ensuring electrical contact between powder material particles in the electrode and between the powder materials and the current collector. Binders have a low mass fraction in the electrode and do not participate in electrochemical reactions. Their primary role is to attach active materials and conductive agents to the current collector, maintaining the integrity of the electrode. Binders influence the formation of the solid electrolyte interface (SEI), charge transfer within the electrode and at the electrode - electrolyte interface, the wetting behavior of the electrode, as well as the battery's cycling performance and cost. Therefore, an ideal binder can guarantee the stability of the electrode structure with the minimum possible usage amount.

Basic Characteristics and Mechanisms of Binders

1. Working Mechanism

The essence of the adhesive force of binders lies in the intermolecular forces (such as van der Waals forces and surface tension), chemical bond forces (such as hydrogen bonds, covalent bonds, and coordination bonds), and interfacial electrostatic attraction. The following are three theories of binder adhesion, as shown in the schematic diagram:

(1) Diffusion Theory Polymer binders penetrate the surface of electrode materials and diffuse into the complex voids within the active materials through molecular Brownian motion. This diffusion occurs at the interface between the electrode material surface and the binder, resulting in a firm bonding effect.

(2) Electrostatic Interaction Theory When the binder and the adhered material system form an electron - acceptor/donor combination, a double - layer can be formed at the interface between the two, generating electrostatic attraction.

(3) Adsorption Theory After the binder diffuses to the electrode surface, an adsorption force is generated between the molecules of the binder and the adhered material. Non - reactive binders mainly rely on intermolecular interactions (van der Waals forces), while reactive binders mainly rely on hydrogen bonds, covalent bonds, coordination bonds, etc. to form interfacial forces.

2: Failure Mechanisms

The destruction or failure of the binder structure can disrupt the paths for ions and electrons and cause the loss of active materials, resulting in capacity fade and safety hazards. The failure mechanisms can generally be attributed to three causes:

(1) Contact Interface Failure

Insufficient adhesive force of the binder prevents it from effectively bonding with the adhered materials, leading to electrode delamination.

(2) Binder Cracking

During battery cycling, the binder is affected by strain and stress changes. When the stress exceeds the yield strength, the polymer undergoes plastic deformation, and the strain cannot fully recover after the stress is removed. When the stress exceeds the ultimate strength, the polymer fractures and fails.

(3) Adherend Fracture

Even if the adhesive force and mechanical strength of the binder meet the requirements, during battery cycling, the cracking and detachment of electrode materials can also lead to a decrease in battery capacity.

In recent years, industry professionals have made significant progress in exploring the working mechanisms and failure mechanisms of binders. However, the structure - property relationships of binders are extremely complex, and there are still challenges in establishing an effective correlation between binder structure and performance. Additionally, due to the small proportion of binders in electrodes, characterization is difficult, and the failure mechanisms in practical applications remain unclear. More sophisticated characterization techniques (such as in - situ characterization) and theoretical simulation calculations are needed to further explore the failure mechanisms of binders.

3: Performance Requirements

Generally speaking, an ideal binder should have six characteristics:

(1) Stable thermal performance to maintain strong bonding force over a wide operating temperature range.

(2) Good mechanical properties, including tensile strength, elasticity, flexibility, hardness, and adhesive strength, to withstand the large volume or strain changes in some special systems, such as silicon (Si) anode batteries.

(3) Good electrical conductivity and ionic conductivity to ensure excellent electrochemical performance.

(4) Excellent dispersibility in solvents to cover and connect the components of the electrode and prevent non - uniform aggregation of the slurry.

(5) Excellent chemical and electrochemical stability to meet the application requirements of different chemical solvents and different voltage windows.

(6) Low cost and environmental friendliness for easy mass production.

Current Status and Research Practices of Lithium - Battery Anode Binders

In lithium - ion batteries, anode adhesives are similar to those for cathodes. They mainly include oil - based PVDF, and water - based CMC, PAMAC, polyvinyl alcohol (PVA), sodium alginate, etc.

1. Adhesives for Graphite Anodes

CMC - based adhesives have currently become the main adhesives for graphite anode materials. Jernei D et al. studied the bonding mechanism of CMC - based adhesives and the failure mechanisms of graphite anodes with different adhesive contents. Four CMC - based adhesives were used, namely methyl cellulose (MC), ethyl cellulose (EC), hydroxyethyl cellulose (HEC), and carboxymethyl cellulose (CMC).

When the mass fractions of the four adhesives in the electrode were 1% and 2% respectively, the test results showed that, compared with the other three adhesives, CMC had the smallest irreversible capacity at both 1% and 2% mass fractions, with a critical mass fraction of 2%. When the CMC mass fraction was 0.25%, when the anode was fully charged, there were brown spots on the surface of the golden - yellow anode (see Figure 3).

Experimental results show that the electrode material at the brown - spotted area is not in a fully - charged state (as indicated by the presence of a LiC₁₂ diffraction peak in the X - ray diffraction spectrum). The reason is that during the electrode charging process, the graphite material on the electrode surface is charged first. Due to the low adhesive content in the electrode, along with the volume expansion of the graphite anode during charging, some of the materials on the electrode surface detach from the main body of the electrode, resulting in a decrease in the reversible capacity of the electrode. The mechanism is that the adhesive forms its own network structure, distributed among the electrode material particles, and the adhesive plays a spatial barrier role. To achieve the bonding effect, a sufficient amount of adhesive is required.

By using gelatin (Fluka. No48722) and CMC as adhesives respectively with the same graphite material, a comparison shows that to achieve an acceptable specific capacity value for the electrode material, the critical mass fractions of the two adhesives are 0.25% for gelatin and 2.00% - 5.00% for CMC.

2. Adhesives for Silicon - Based Anodes

Silicon anode materials are one of the current research focuses in lithium - ion battery materials. Silicon has a high theoretical capacity of up to 4200 mA·h/g and a low lithiation - delithiation potential (0 - 0.4V vs. Li/Li+). Compared with other metal and alloy anode materials, it has a relatively low first - cycle irreversible capacity. Moreover, it is abundant in nature and has a low raw material cost, making it a promising lithiated anode material.

However, during the lithiation - delithiation process, pure silicon materials have a high expansion - contraction ratio (with an expansion rate of up to 400%), resulting in structural pulverization and poor contact between the active material and the current collector. After several cycles, the electrode capacity decays significantly.

Currently, to improve the electrochemical performance of silicon - based materials, the following methods are mainly adopted:

(1) Controlling the electrode porosity.

(2) Effectively distributing silicon materials in the electrode.

(3) Developing functional binders for high - specific - energy batteries.

Currently, the lithium - battery anode binder industry is facing a series of technological innovation challenges, such as how to improve adhesion, reduce production costs, and enhance battery reliability and cycling performance. With the continuous optimization and iteration of technology, the industrialization development of fluorine - free binders, the complexity, cost, and environmental friendliness of PAA and PTFE modification processes are also important considerations and bottlenecks to be broken through in future research.

——End——

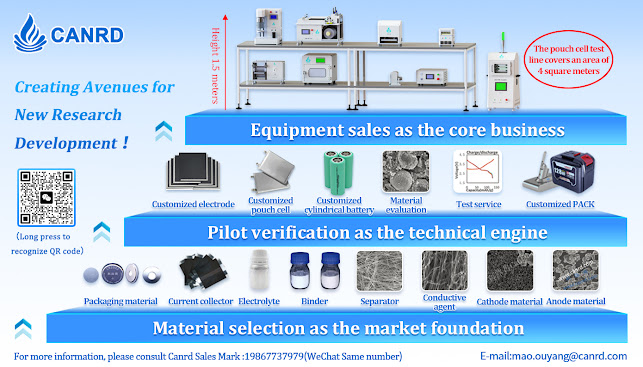

Canrd Brief Introduce:�Canrd use high battery R&D technology(core members are from CATL) and strong Chinese supply chain to help many foreign companies with fast R&D. We provide lab materials, electrodes, custom dry cells, material evaluation, perfomance and test, coin/pouch/cylindrical cell equipment line, and other R&D services.

Email:Eden@canrd.com

Phone/Wechat/WhatsApp/Skype:+86 13713092381