LIBs electrodes are mainly composed of electrochemically active electrode materials, conductive additives, binders, current collectors, etc. Among them, binders are an important component of LIBs electrodes. Binders can tightly attach active substances and conductive agents to the current collector to form a complete electrode, prevent the active substances from falling off and peeling off during the charge and discharge process , and can evenly disperse the active substances and conductive agents, thereby forming a good electron and ion transmission network and realizing efficient transmission of electrons and lithium ions.The materials currently used as electrode binders include polyvinylidene fluoride (PVDF), carboxymethyl cellulose (CMC), styrene-butadiene rubber (SBR), polyvinyl pyrrolidone (PVP), polymethyl methacrylate (PMMA), polyacrylonitrile (PAN), polyacrylic acid (PAA), polyvinyl alcohol (PVA), sodium alginate (Alg), β-cyclodextrin polymer (β-CDp), polypropylene emulsion (LA132), polytetrafluoroethylene (PTFE), etc., as well as functional derivatives of the above polymers or copolymers between monomers .In LIBs electrodes, ideal binder properties should include:(1) It has chemical and electrochemical stability in a given electrode/electrolyte system, is resistant to electrolyte corrosion , and does not undergo redox reactions within the operating voltage range;(2) It has good solubility , dissolves quickly in the solvent, has high solubility, and the required solvent is safe, environmentally friendly, and non-toxic, with water being the best solvent;(3) The viscosity is moderate, which is convenient for homogenization and maintaining the stability , and the bonding force is strong. The prepared electrode has high peel strength, good mechanical properties, and low binder dosage;(4) Good flexibility, able to withstand bending during electrode operation and volume changes of active material particles during LIBs charge and discharge cycles;(5) It can form an ideal conductive network with the conductive agent, and the prepared electrode has good conductivity and lithium ion conductivity;(6) Wide sources and low cost.This paper summarizes the research results related to LIBs electrode binders in recent years, focusing on the adhesion mechanism of binders in electrodes and the oil-based and water-based binders commonly used in LIBs electrodes .1 Adhesion mechanism of binders in lithium-ion battery electrodesThe LIBs electrode production process usually includes four steps: mixing various materials (including electrode active materials) in a solvent to make a battery slurry, coating the slurry on the current collector, drying and rolling. It is generally believed that LIBs electrodes contain three parts: active material particles (AM) as ion and electron sources, pore spaces filled with electrolytes for ion conduction, and carbon-binder domains (CBD) that provide conductivity .

.webp)

CBD is usually made of carbon nanoparticles connected (Figure 1), and the precursor slurry required for preparing electrodes is composed of micron-sized AM particles suspended in CBD. CBD directly affects the transmission efficiency of ions and electrons in the electrode, as well as the quality of the passivation layer (such as SEI and CEI films) formed on the surface of the active material in contact with the electrolyte. Therefore, CBD plays a vital role in the electrode manufacturing process: too little CBD will lead to insufficient electrode connectivity, resulting in poor electron transfer and insufficient mechanical strength of the electrode; while too much CBD will increase the weight and volume of the battery, and even slow down the transmission .Zielke et al. used a new method combining X-ray tomography and virtual design to compare the effects of two CBD models on the surface area, curvature and conductivity of the solid . The results showed that the CBD content has a great , while the morphology of the CBD only has an important influence on the discharge state of LIBs.Prasher's team proposed a microrheological model that includes interparticle colloidal interactions and fluid dynamic interactions, and predicted the viscosity of the conductive carbon nanoparticle and polymer binder suspension and even the entire anode slurry. They found that the interaction between carbon nanoparticles largely depends on the ratio of particles to polymer binder and the molecular weight of the polymer binder, and that changes can be clearly reflected in the assembly structure of the particles, and thus in the viscosity of the slurry.Srivastava et al. used particle dynamics and colloidal dynamics simulations to illustrate the effects of AM-CBD adhesion and CBD cohesion on electrode microstructure and key properties related to electrochemical transport (such as ion transport tortuosity, electronic conductivity, and available AM-electrolyte interface area), as shown in Figure 2.

.webp)

When the cohesive force is high , the phenomenon of CBD aggregation around AM particles is significantly suppressed, and CBD preferentially forms a network gel, thereby obtaining a larger AM-electrolyte interface area [Figure 2 (b)]. This explains why the cohesive force of CBD and the adhesion between AM and CBD significantly affect the electrochemical transport-related properties of the electrode. Based on this, a to design the LIBs electrode structure by controlling the cohesive force of CBD and the adhesion between AM particles and CBD, thereby enhancing the electrochemical transport-related properties of the electrode , providing a solution for the optimization of the LIBs electrode microstructure.2 Commonly used lithium-ion battery electrode binders2.1 Polyvinylidene fluoride (oil-based)Polyvinylidene fluoride (PVDF) is one of the earliest used binders. It has high mechanical strength and a wide electrochemical stability window. It is widely used as a binder for battery electrodes in various systems, including LIBs. In the large-scale production of lithium-ion batteries , highly polar organic compounds such as NMP and DMF are often used as solvents to prepare PVDF into an oil-soluble solution, which is then used as a binder for lithium batteries.

.webp)

Zhong et al. investigated the bonding mechanism of AM and PVDF in LIBs through DFT simulation calculations and analysis of the bonding surface between AM particles and binders in LIBs electrodes (Figure 3). The results of process simulation and theoretical calculations show that in LFP batteries, the bonding effect between LFP and PVDF is much greater than that between PVDF and Al, while in NCM batteries, the bonding effect between NCM and PVDF is weaker than that between PVDF and Al; scanning electron microscopy and Auger electron spectroscopy (AES) analysis show that in LFP batteries, PVDF is mainly distributed on the LFP surface, which indicates that PVDF has poor bonding performance in LFP batteries, while in NCM batteries, PVDF is evenly distributed on the active material and Al surfaces, which indicates that PVDF has good bonding performance in NCM batteries. The research results show that the development of new binders should focus on strengthening the bonding effect between binders and Al, and confirm that the main physical interaction between AM, Al and PVDF in LIBs is physical interaction, not chemical interaction.2.2 Carboxymethyl cellulose and styrene-butadiene rubber (water system)Carboxymethyl cellulose (CMC) is a linear polymer derivative , which is formed by natural cellulose being replaced by carboxymethyl groups to varying degrees . CMC is a polybasic weak acid that can dissociate to form carboxylate anion functional groups. At the same time, the presence of carboxymethyl groups makes CMC more soluble in water than ethyl cellulose (EC), methyl cellulose (MC) and hydroxyethyl cellulose (HEC). This enables CMC to achieve electrode production with water as a solvent, which is more advantageous than PVDF in terms of low cost , non-toxic and harmless production. The free carboxylic acid groups in CMC can interact with the hydroxyl groups on the surface of materials such as silicon/carbon to form an ideal CBD network in the electrode. CMC is low in cost, has good thermal stability and is environmentally friendly, so CMC is considered to be a potential binder for the anode in LIBs.Lee et al.'s research shows that the graphite slurry using CMC with a lower degree of substitution as a binder has better suspension stability. This is because CMC with a lower degree of substitution has stronger hydrophobicity, which enhances its interaction with the graphite surface in the aqueous medium. Drofenik et al.'s research shows that the use of a small amount of CMC (2% by mass) in a graphite negative electrode can achieve the desired effect of a large amount of PVDF (10%) binder, and will not affect the normal deintercalation of lithium ions in the graphite electrode and the formation of the SEI film. This shows that the use of CMC can reduce the amount of binder used, which is beneficial to improving the energy density of LIBs electrodes, and is an excellent LIBs anode binder.However, CMC water-based binder has strong rigidity and brittleness. After vacuum drying, cracks are clearly visible on the surface of the electrode with CMC as binder, which may cause gaps between the electrode material coating and the current collector, causing the electrode to "fall off". To solve this problem, Liu et al. used styrene-butadiene rubber (SBR) as an elastic additive for CMC binder , compared the effects of SBR-CMC composite binder and traditional PVDF binder on the cycle stability of silicon (Si) anode, and explored the mechanical properties and swelling behavior of SBR-CMC composite binder in electrolyte solution. The results show that the addition of SBR can effectively reduce the brittleness of the electrode; compared with PVDF binder , Si anode using SBR-CMC composite binder shows a smaller Young's modulus, a larger maximum elongation, and a stronger adhesion strength to the current collector.The research of Dahn's group showed that Si electrodes have better capacity retention than Si electrodes made with CMC binders alone. At the same time, their research revealed that since CMC is a very hard and brittle polymer, CMC aqueous binders work well as binders in electrodes with a large volume change rate of active material particles. However, CMC aqueous binders absorb less organic carbonate electrolytes than PVDF, which may affect the rate performance of electrodes with CMC as a binder.In addition, CMC has been used as an additive to improve the cycling stability of LIBs (such as Si and Sn alloys) anodes, which show large volume changes during battery cycling . The mechanism of improved cycling performance is believed to be: (1) Si and carbonaceous conductive additive particles are bridged by CMC chains; (2) CMC forms stable covalent bonds (Figure 4) or self-healing hydrogen bonds on the surface of .

2.3 Polyacrylic acid binder (water-based)Polyacrylic acid (PAA) is a water- soluble . Due to the presence of a large number of carboxylic acid groups in its structure (Figure 5), it can form strong interactions with active substances and aluminum foil, and thus has good bonding properties . It is a potential high-performance binder for LIBs electrodes. In addition, during the LIBs cycle, PAA can help form a stable CEI and improve the cycle stability .

.webp)

Su et al. used PAALi as a binder and investigated the Li+ transport behavior in PAALi and its effect on the electrochemical performance of LIBs. The results showed that the new PAALi binder exhibited and had good adhesion to all electrode components , thus forming a continuous conductive network in the electrode . The capacity retention rate of the LVP battery using the new PAALi binder was 91% after 1400 cycles at 10C. They showed through Fourier transform infrared spectroscopy (FTIR) and X-ray photoelectron spectroscopy (XPS) that the PAALi binder can promote the transport of Li+ at the electrode interface through the reversible exchange reaction of H+/Li+ between -COOH and -COOLi (Figure 6). This highly coordinated enhances the kinetic performance of the electrode and provides a fast capacitive redox process, which enables it to obtain an excellent .

.webp)

Chong et al. studied the half-cell and full-cell electrochemical performance of graphite/LiFePO4 battery systems with PAA containing SBR as a binder and PVDF as a binder. The results showed that PAAX (X=H, Li, Na, or K) can effectively improve the initial coulombic efficiency, reversible capacity and cycle stability of graphite The addition of a small amount (0.5%~3.0%) of SBR avoids the formation of brittle cracks after electrode drying. Among the PAAX series of binders, PAALi and PAANa have better battery performance, which is attributed to their ability to form a more favorable polymer conformation (CEI) in the electrode composite material . At the same time, the water-based PAAX series of binders can reduce the manufacturing cost of graphite/LiFePO4 batteries and reduce environmental damage.Although the binder in the LIBs electrode is an electrochemically inactive material, it can form a CBD structure together with conductive carbon nanoparticles. When the adhesion between the binder and the current collector is good, a good CBD conductive network can be formed by adjusting the cohesive force of the CBD and the adhesion between the AM-CBD, which not only makes the electrode have strong mechanical strength and peeling strength, but also forms a conductive network inside the electrode that is conducive to electron conduction, so that the electrode has good electron transfer efficiency; it also helps to increase the AM-electrolyte interface area used for ion conduction, reduce the tortuosity of ion transfer in the electrode, and improve the quality of the passivation layer (such as SEI, CEI film) formed on the AM surface , thereby having an important impact on the electrochemical performance of the electrode.At present, the commonly used LIBs electrode binders mainly include the oil-based binders represented by PVDF introduced in this article and the water-based binders represented by CMC, SBR, and PAA . PVDF has good adhesion to the current collector, and its molecular weight can be changed by adjusting the degree of polymerization of vinylidene fluoride (VDF), thereby adjusting its adhesion. It is currently widely used in the production of electrodes for various battery systems. Compared with the oil-soluble binder PVDF, water-based binders such as CMC, SBR, and PAA do not require the use of organic solvents in actual use, avoiding the pollution of the environment by high-temperature organic solvent vapor and the damage to the health of operators. Moreover , among the water-based binders, CMC, as a derivative of cellulose, has the characteristics , which meets the requirements of low-cost LIBs. It can also be used as an additive to improve the cycle stability of silicon negative electrodes and has broad application prospects; PAALi binders have good bonding properties and can supplement the consumption of active lithium in LIBs during the cycle process, showing great development potential, and are expected to open up a new path for the development of high-performance binders for LIBs.

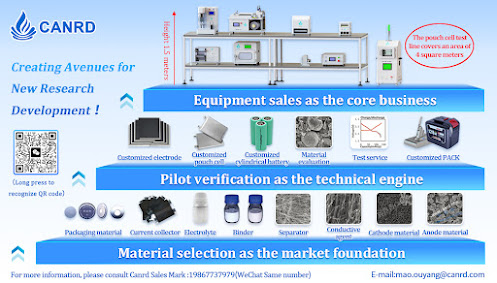

Canrd Brief Introduce

Canrd use high battery R&D technology(core members are from CATL) and strong Chinese supply chain to help many foreign companies with fast R&D. We provide lab materials,electrodes, custom dry cells, material evaluation, perfomance and test, coin/pouch/cylindrical cell equipment line, and other R&D services.

Email:janice@canrd.com

Phone/Wechat/WhatsApp/Skype:+86 18928276992

Website : www.canrud.com

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

No comments:

Post a Comment