1.Process Flow

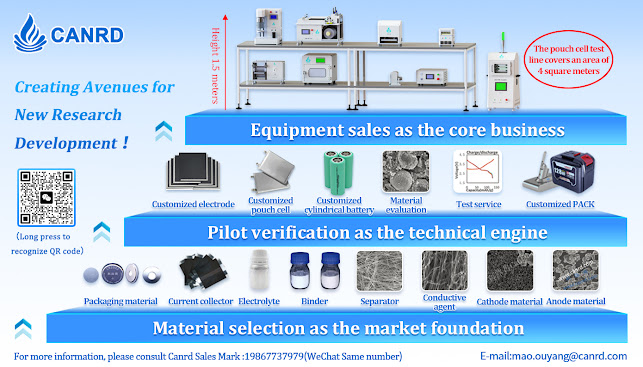

The main components of a lithium battery include a positive electrode with an active material typically being lithium cobalt oxide, a separator made of PP or PE composite membrane, a negative electrode with carbon as the active material, organic electrolyte, and a battery case made of aluminum-plastic composite film. The manufacturing process involves slurry preparation, film coating, assembly, and formation. In recent years, electronic products have become increasingly thinner and lighter, with faster charging speeds and reduced space, resulting in higher demands for the energy density of lithium batteries. Lithium batteries need to be continuously updated and improved to meet these demands, further trending towards smaller, lighter, and thinner batteries. The related topics of lithium batteries have always been a hot research focus. Adopting suitable materials and cell manufacturing processes can improve battery performance. For specific materials and processes, please consult Canrd!