The eighth lecture of the Kelude full battery production forum - Packaging

Packaging material introduction

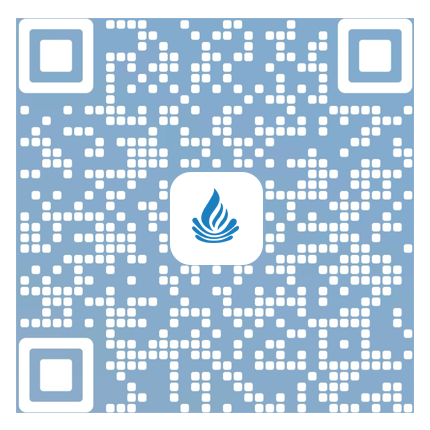

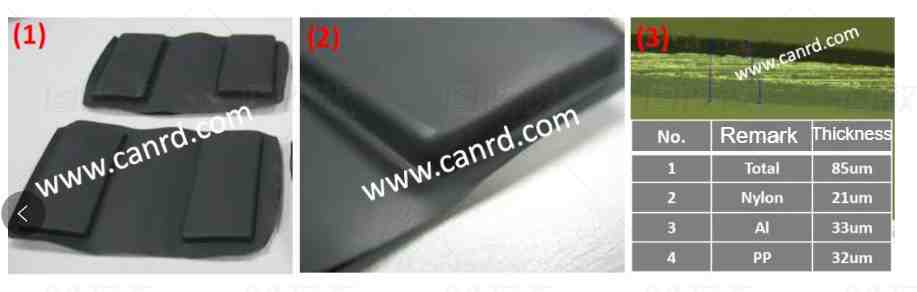

First, there are two main materials used in the packaging process: aluminum-plastic film and tabs. Figure (1) above is a physical picture of the aluminum-plastic film. Currently, aluminum-plastic film has two appearances: silver and black. Apple mobile phone batteries are mainly the latter, while others are mainly the former. The aluminum-plastic film is mainly composed of three layers: from the inside to the outside, they are PP, Al and Nylon layers, and each layer has its own function, as shown in the table above. The tabs are mainly composed of Al strips or Ni strips plus two layers of PP, as shown in Figures (3) and (4) above. Currently, most aluminum-plastic films are imported, and some domestically produced ones are available, mainly low-end products. The thickness of the aluminum-plastic film ranges from 68 to 153um.

Packaging material introduction - Flushing

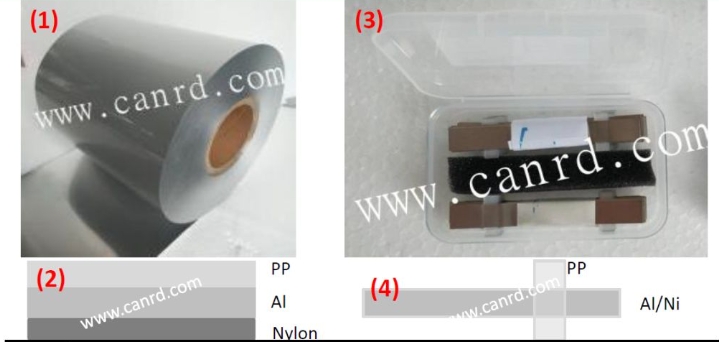

The stress and strain distribution of the pocket is symmetrical.

The maximum stress and strain occur at the corner of the pocket.

The stress and strain on the short side are greater than those on the long side.

One of the most important properties of aluminum-plastic film is the punching performance, and the most intuitive way to show it is the maximum depth of the punching. For the punching of aluminum-plastic film, the top corner position has the largest pull-up and is most likely to break, so the maximum punching depth is assessed by assessing the characteristics of the top corner position. The punching depth of aluminum-plastic film of different thicknesses varies from manufacturer to manufacturer, so don’t buy it casually, but consult manufacturers with technical strength, and let them give you some usage suggestions, otherwise it will be troublesome if there are some damage and corrosion problems after buying it back. At present, aluminum-plastic film with better quality is mainly produced by three Japanese companies: DNP, Showa, and Toppen; there are many domestic aluminum-plastic film manufacturers, but the quality is quite different from these three. In addition, there is a parameter that many peers may not pay much attention to. For production, the maximum punching depth of aluminum-plastic film is not the depth of the top corner, but the thickness of the Al layer in the aluminum-plastic film at the top corner is not less than 20um (the relaxed standard is 17um) as the basis for judgment.

Punching performance

Appearance after punching

Thickness distribution of each layer of aluminum-plastic film

As shown in the figure above, when the aluminum-plastic film is cut, the thickness of each layer is measured. The total thickness is 85um. The thickness of Nylon, Al, and PP are 21um, 33um, and 32um respectively (the factory specifications are 20, 35, and 30). Due to test errors, thickness fluctuations and other factors, there is a slight deviation between the measured value and the shipped value.

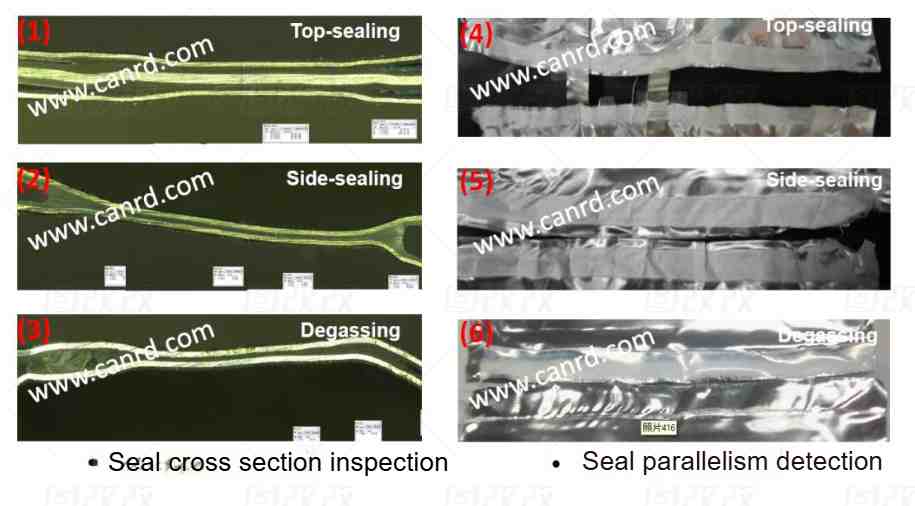

Aluminum plastic film packaging performance

The important basis for evaluating the quality of aluminum-plastic film packaging is as shown in the figure above - look at the seal section and the parallelism of the seal. The cross-section of the seal is to observe the packaging effect perpendicular to the sealing direction, mainly to intuitively observe the seal appearance and the thickness of the PP after melting. The above figure (1) is the sealing interface of the top seal, and it is also necessary to observe the parallelism between the pole ear (white in the middle) and the two aluminum layers of the aluminum-plastic film (white strips on both sides). The more parallel the better (top seal short circuit, many times it is caused by the pole ear and the aluminum layer are not parallel, or even directly in contact). The above figures (4) to (6) are after packaging, tearing the seal open with force to observe the sol effect; among them, the top side seal is white and uniform and continuous, which is the best; when DEG (second seal) is sealed, different materials have different shapes, and the main thing is to be uniform and continuous.

Tab sealing performance

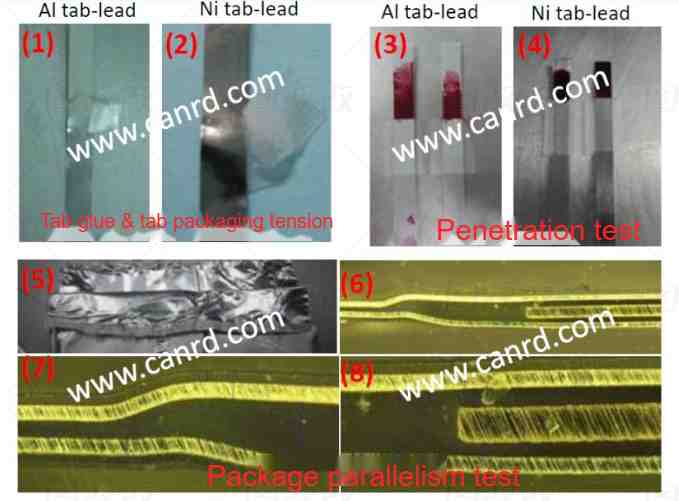

Tabs mainly include aluminum tabs and nickel tabs. The former are used for positive electrodes, and the latter are used for negative electrodes. The quality of tabs is mainly determined by the adhesion between the tab glue and the tab metal. They are mainly evaluated by peeling, penetrant penetration, etc., as shown in Figures (1)-(4). In addition, the tabs are evaluated in the same way as aluminum-plastic films, and the cross-sections and parallelism tests are performed after packaging. Tabs also have different thicknesses and widths. According to product requirements, batteries with large capacity and high rate generally require wide and thick tabs.

Packaging technology-packaging process

The two layers of aluminum-plastic film PP face each other. The head is heated and pressurized to melt the PP layer.

The two layers of PP are completely melted together to form a whole to achieve a sealing effect.

The packaging process is shown in the figure: it is the process of placing two layers of PP of aluminum-plastic film opposite each other, applying pressure and temperature through the sealing head, so that the two layers of PP are fused together. In order to ensure the reliability of packaging, the deformation rate of PP is generally between 25%-70%.

Packaging process-Packaging naming

There are five common types of soft-pack battery packaging: top seal, side seal, corner pre-packaging, vacuum packaging, and DEG (secondary sealing). The yellow area indicates the location of the packaging. As shown in the figure above, it corresponds to the specific location of each package. Among them, top seal, side seal, and DEG (secondary sealing) are the most critical; and to control the packaging well, the most important thing is to debug the packaging machine, which is the core. If the packaging is not done well and the battery leaks, then the battery is basically scrapped, so packaging is very critical.

Packaging process - top seal

Packaging process One side sealing

Packaging process-DEG

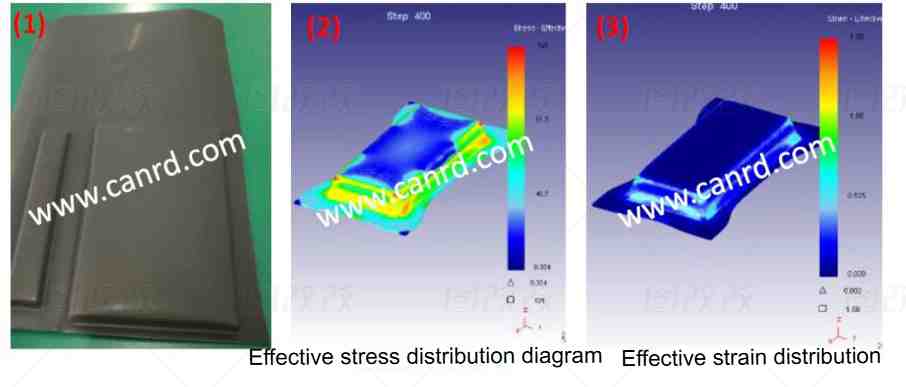

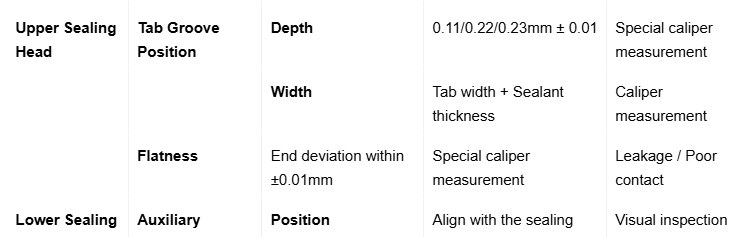

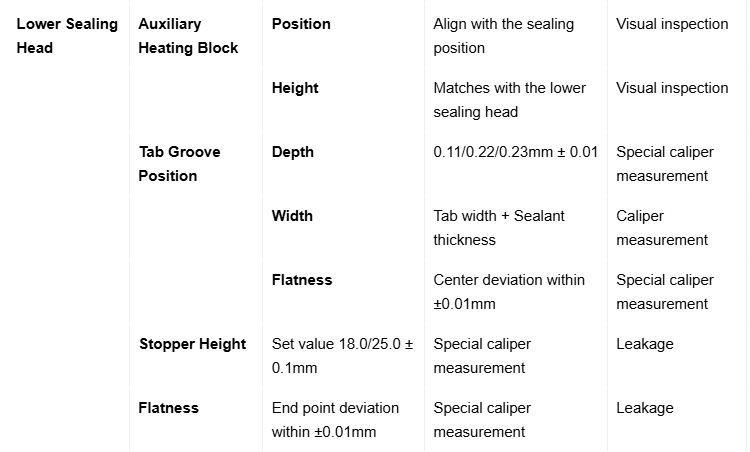

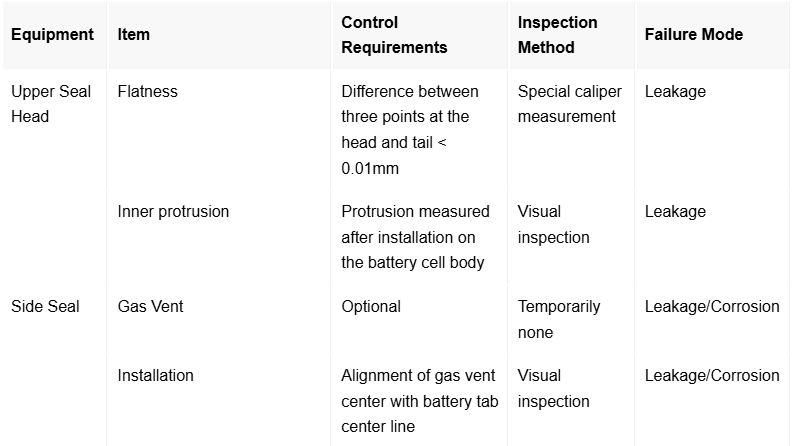

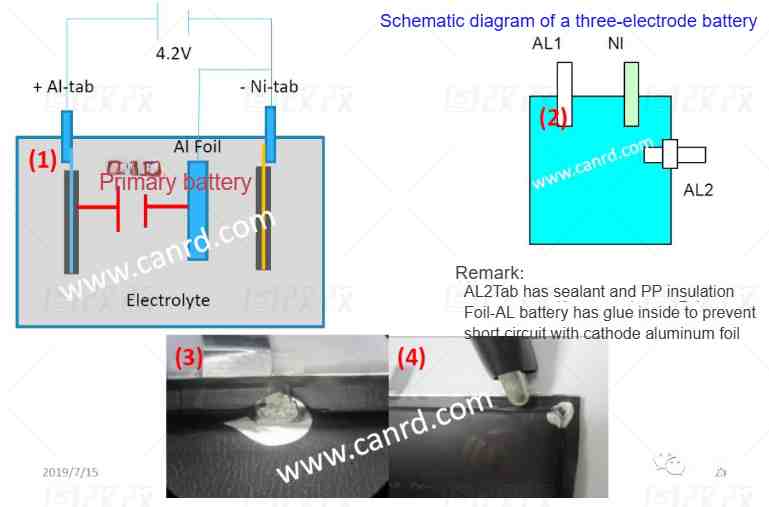

| Process | Item | Control Requirements | Inspection Method | Impact | Failure Mode |

|---|---|---|---|---|---|

| Degassing/Secondary Seal | Distance between seal and main part | Degassing: 0.5~1.5mm; Secondary Seal: 1.5~2.5mm | Visual inspection/Caliper | Easily causes PP breakage; insufficient margin after sealing | Leakage/Corrosion |

| Overlap size with top seal | >1mm | Visual inspection/Caliper | Misalignment with top seal may affect adhesion | Separation | |

| Seal width | >1.5mm | Visual inspection | Ensures seal integrity | Separation | |

| Seal folding | Not allowed | Visual inspection | PP film folding affects seal completely | Leakage | |

| Seal thickness | Not currently defined (recommended: 0.17~0.20mm) | Visual inspection | Insufficient PP thickness may impact seal effect | Leakage/Breakage | |

| Seal flatness | No bulges | Visual inspection | PP film bulges after sealing may cause gaps | Leakage | |

| Packaging | Equipment | Defined by WI files | Visual inspection/Measurement | Inconsistent packaging could impact sealing process | Leakage/Short circuit |

| Time | Defined by WI files | Visual inspection/Timer | Insufficient or excessive time could weaken seal | Leakage/Corrosion | |

| Pressure | Defined by WI files | Visual inspection | Excessive pressure may break PP film; insufficient pressure may cause weak seal | Leakage | |

| Vacuum level | Defined by WI files | Visual inspection | Insufficient vacuum level may lead to gas remaining inside | Expansion |

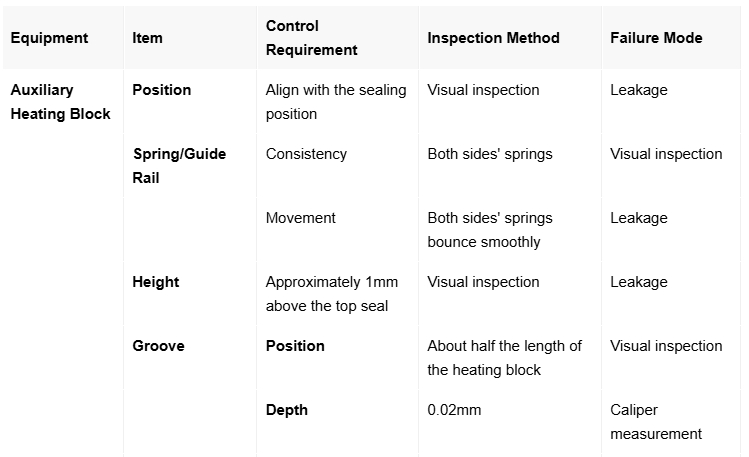

The above is a detailed description of the packaging machine adjustment. It is all practical experience and must be combined with the corresponding packaging machine; therefore, no specific explanation is given here.

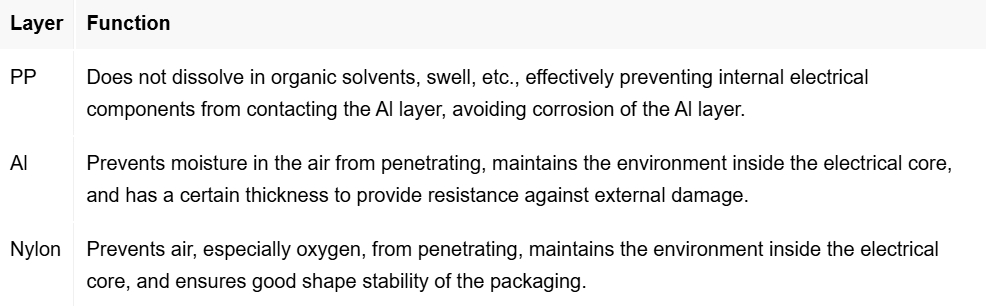

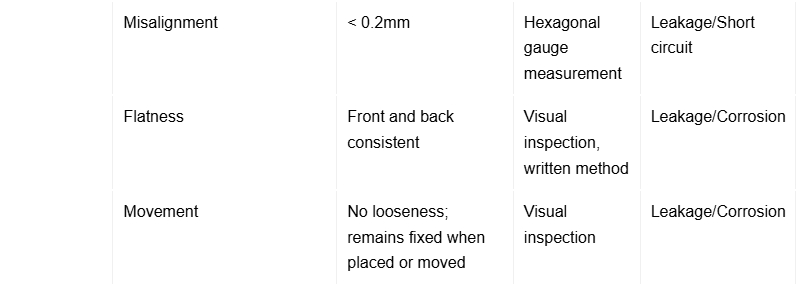

Packaging process - corner pre-sealing

Corner pre-packaging is something that many teachers may not have encountered. As shown in the above figure (1) and (3), it is a simple packaging at the two bottom corners of the battery cell so that the two layers of aluminum-plastic film stick together. The main purpose is to increase the bending resistance of the bottom corners. The above figure (2) shows the bottom corner damage caused by bending. The main reason is shown in the above figure (4). During the battery production process, the battery cell air bag is often touched, causing the intersection of the air bag and the battery body to bend back and forth, resulting in damage.

Key packaging technology: anti-leakage

Leakage: There is no (or "weak") fusion or bonding between the two layers of PP. Possible reasons: Abnormal aluminum-plastic film, foreign matter between seals, uneven seal heads, abnormal packaging temperature.

Package leakage is easy to understand. It means that the seal is not completely fused together during packaging, resulting in poor sealing effect and leakage. As shown in the figure above, this is a failure reason for package leakage. This is also easy to check: generally tear off the seal and observe directly.

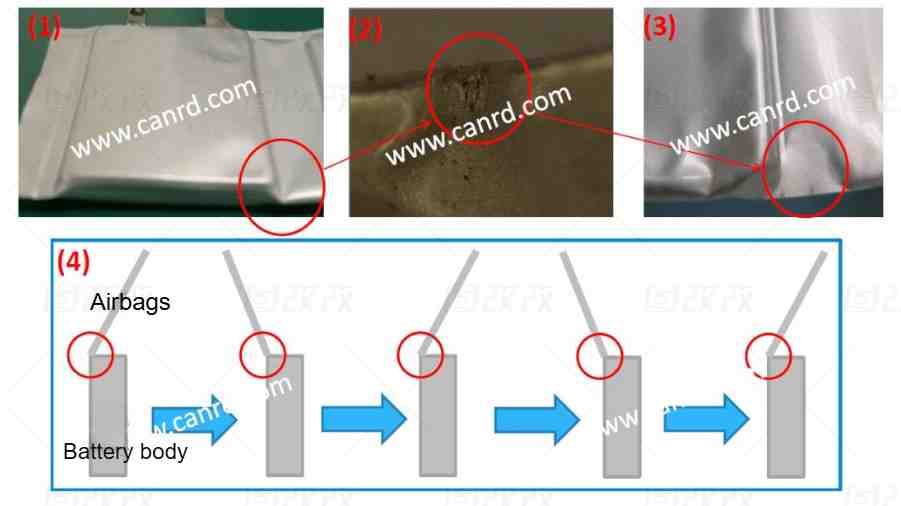

Key packaging technology: anti-corrosion

Package corrosion problem is also a common problem. For this package problem to occur, two conditions must be met:

1. There is a short circuit or micro short circuit between the Ni tab and the Al of the aluminum-plastic film; 2. The Al layer of the aluminum-plastic film is in contact with the electrolyte (that is, the PP layer is damaged). At this time, the Al layer of the aluminum-plastic film will form a primary battery structure between the positive electrode and discharge spontaneously, and then the Al layer of the aluminum-plastic film will act as the negative electrode and undergo a dissolution reaction.

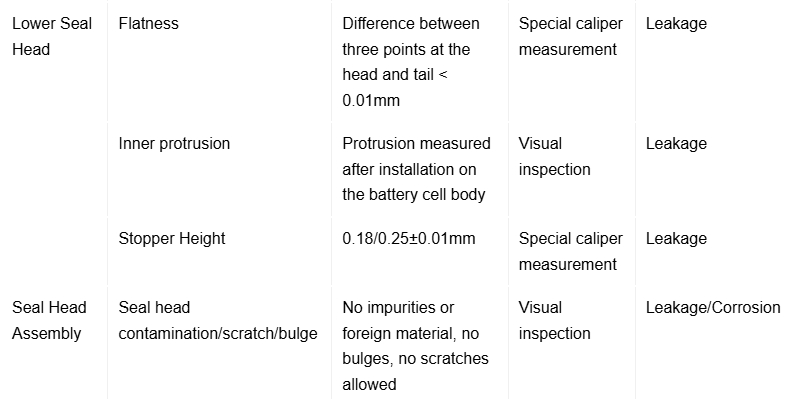

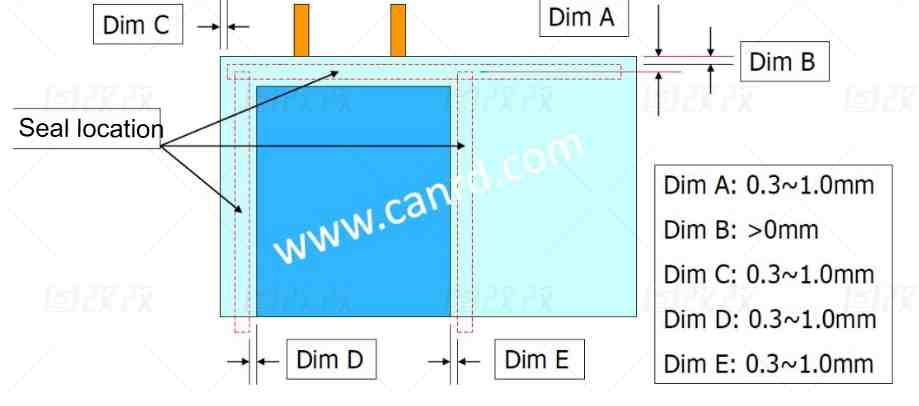

Key packaging technology-critical dimensions

A: Prevent glue overflow from contaminating the top seal

B, C: External unsealed area, prevent contamination of the seal:

D, E: Internal unsealed area, after folding, the imprint becomes larger, resulting in complete exposure of the AI layer.

Finally, there is another very important assessment indicator for packaging: key dimensions. To achieve excellent packaging effects, the size of the seal must be strictly controlled. The figure above briefly summarizes the values of several core packaging dimension indicators. You can refer to the above. This is a simple introduction to packaging. Thank you for watching! Next is the recording part of the Q&A session.