The seventh lecture of the Kelude full battery production forum - Slitting and winding

The last class mainly introduced the rolling process of the pole piece. Today we will start to introduce the processes after rolling - stripping, welding, gluing, and winding. These contents are relatively simple.

Striping

Battery factories use semi-automatic and automatic slitting machines for slitting,

while universities mostly use manual cutting (the burrs on the pole pieces are difficult to control)

After the large roll of pole pieces is rolled, in order to obtain the required size, we also need to cut the large roll of pole pieces into pole piece strips of a certain width. At present, the commonly used equipment in industrialization are semi-automatic slitting machines and automatic slitting machines. In order to facilitate slitting and control the length of the pole pieces, if an automatic slitting machine is used, the pole pieces need to be cut before slitting - the continuous pole pieces are cut into large pieces according to the length of the pole pieces, and then slitting is performed. The slitting effect is as shown in the middle picture above. For the automatic slitting machine, the whole process is driven by the transmission device. You only need to roll the rolled pole pieces onto the machine, and after adjusting the slitting knife, you can perform the integrated operation of slitting and winding without cutting, which is very convenient; some universities also make some soft-pack batteries. Due to the small quantity and lack of equipment, they may be cut manually with a blade. The process is very simple, but burrs are often prone to appear in the cutting of the pole pieces, which leads to the problem of large self-discharge of the battery in the later stage. At the same time, the following problems are also prone to occur during the slitting process

Striping Problem

Burrs are the most important control point in the slitting process

For example, after slitting, the pole piece deviates, causing some pole pieces to be cut to waste. This mainly occurs in the semi-automatic slitting process. Because the semi-automatic slitting is manually controlled by the feeding of the film, the pole piece is not aligned with the baffle or the edge baffle is crooked when feeding the film, which may cause the pole piece to deviate and the edge of the pole piece to be cut unevenly. This is mainly because the knife is not fast, which will make it easier to drop the material. Therefore, we must regularly check whether the slitting knife is sharp and whether there is rust. Strip wrinkles are mainly caused by insufficient tension in the slitting process, so during operation, the tension of the stripping should be controlled well. If it is a semi-automatic slitting machine, the tension is controlled by people-when feeding the film, the pole piece should be lightly pressed while feeding the film to keep the pole piece in a straight state. Here is a phenomenon: for the manual slitting equipment used in our laboratory, it is easy to have an "S" shape in the length direction of the strip, that is, the edge of the strip is not a straight line (this can be checked with a ruler), which will cause uneven winding, and in severe cases, the pole piece will be damaged. Teachers who use laboratory slitting equipment need to pay special attention; this problem will not occur when using automatic slitting equipment; of course, the most important thing in the slitting process is to control burrs, which may cause internal short circuits in the battery and even cause safety problems such as thermal runaway.

Striping Problem

Through CCD observation, the position and size of the burr are determined (generally the length of the burr cannot be greater than 1/2 of the diaphragm) to prevent the battery from internal short circuit and safety problems.

In order to solve the burr problem, here is a commonly used detection method, CCD detection, using a microscope to magnify and measure the burr state after the pole piece is stripped, to see the position of the burr, whether it is parallel to the pole piece or perpendicular to the pole piece, and the length of the burr. Generally speaking, the length of the burr is controlled to be less than 1/2 of the diaphragm, so that even if there are burrs, it is difficult for the burrs to pierce the diaphragm and cause an internal short circuit.

Welding

At present, most battery factories use ultrasonic welding to weld pole pieces and pole ears, with aluminum pole ears used for positive poles and nickel pole ears used for negative poles.

After the stripping, the welding will be done. Generally, the positive aluminum foil uses aluminum-to-nickel tabs, and the negative copper foil uses nickel tabs. They are welded together by an ultrasonic welding machine. There are two problems to avoid in this process: over-welding and cold welding. Simply put, welding is one of over-welding, which penetrates the foil, resulting in insufficient welding strength. In the subsequent process, the foil and the tab are prone to fall off. The other is cold welding, which means that the welding strength is not enough, resulting in no effective welding, large welding internal resistance, and the tab is also prone to fall off.

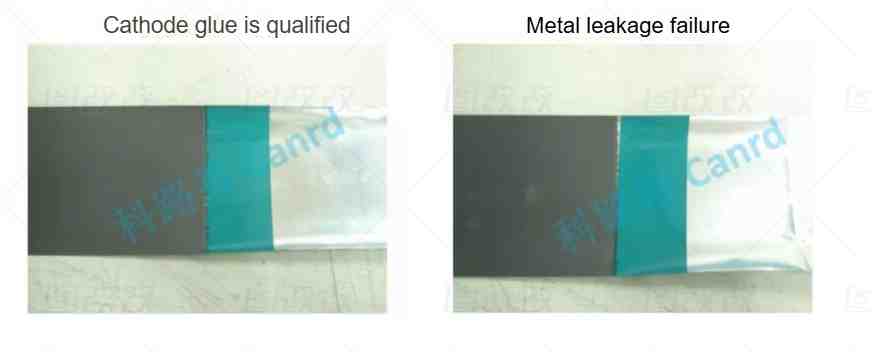

Glue

The purpose of gluing is to prevent the burrs at the welding position from piercing the diaphragm and causing a short circuit, and also to control the powder falling off the edge of the electrode.

After welding is completed, the glue process will be carried out, but this tape is a special tape that needs to withstand immersion in the electrolyte. When we talk about special glue here, we actually want to tell you that the glue here is different from ordinary tape: first, there will be no other components that are soluble in the electrolyte, and second, this green glue can still be sticky after being soaked in the electrolyte. There are several main purposes of glue sticking. One is that the position after welding needs to be glued, because the welding position often has a deeper weld mark and a rough surface. In the subsequent shaping process, it may cause puncture of the diaphragm and cause a short circuit. In addition, the edge of the pole piece material area will be affixed with green glue to prevent material falling. Of course, sometimes this green glue is also used to control the coating area in the length direction to ensure that the overhang is sufficient during winding.

Glue problem

Green glue needs to effectively cover the edge area of the diaphragm

The left picture shows the correct way to glue the material area. If you look closely, you can see that the glue on the right does not completely cover the interface between the coating area and the foil area, which is not standard.

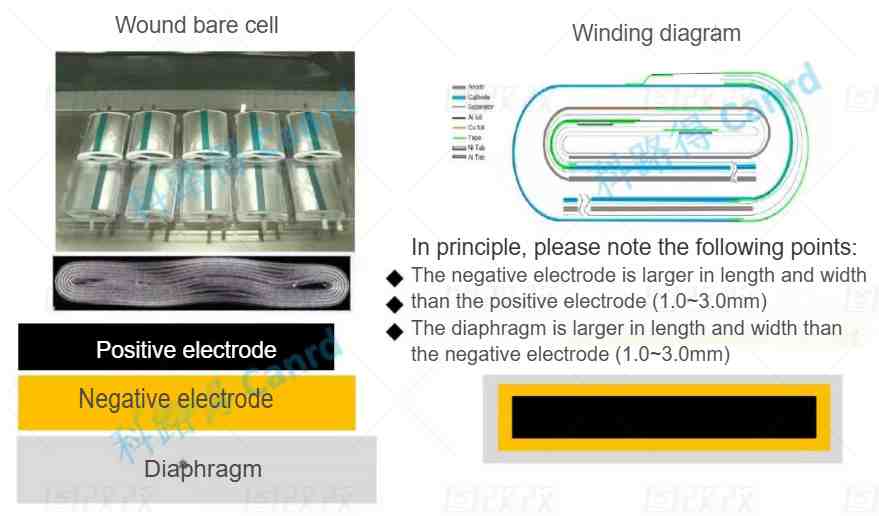

Winding

This is the overall situation of winding. After winding, we call it a bare cell. In fact, it is to pass the electrode through the winding needle and roll it into a bare cell of a certain width. Here we should pay attention to controlling the coverage area. Generally, the diaphragm should completely cover the negative electrode, both in width and length, and the negative electrode should completely cover the positive electrode. In this way, it can effectively ensure that the lithium ions from the positive electrode can be fully received by the negative electrode, so that lithium plating will not occur, which will eventually lead to safety hazards.

Pole piece inspection before winding

Before winding, we need to do some inspection of the pole pieces. Generally, pole pieces with appearance similar to the following will be judged as unqualified, such as pole piece damage, negative pole piece falling off, etc. These are all safety risks, and the pole pieces need to be picked out.

Winding Problem

These are the most common problems. We should still follow the previous principle to judge: the diaphragm should cover the negative electrode, and the negative electrode should cover the positive electrode to ensure overhang. In the right picture, the negative electrode is not effectively finished at the positive electrode glue position, so the burr problem at the negative electrode cutting edge cannot be solved, so it is also unqualified.

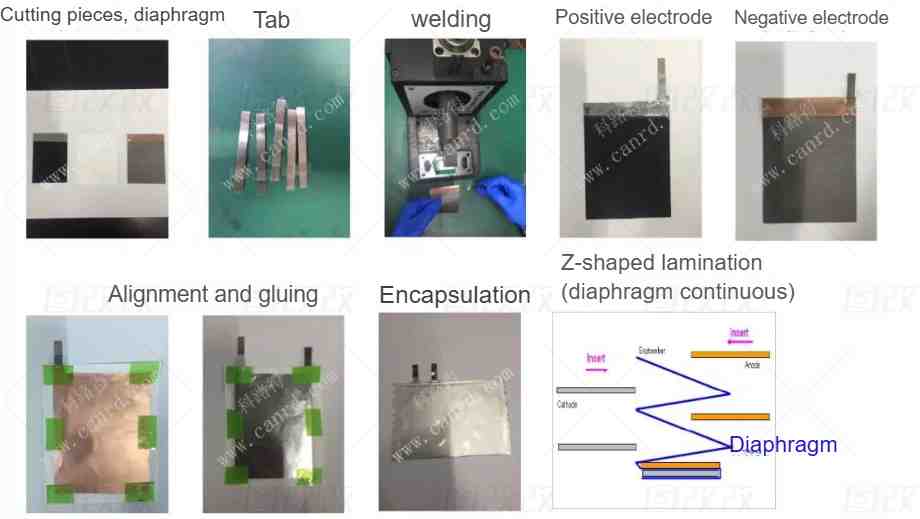

Lamination

Finally, let's take a look at the lamination process. The lamination principle is similar to the winding process, and the main difference is in the pole piece. The pole piece here does not need to be divided into strips, but cut into small pieces according to the size requirements, and then welded and glued, and then the alignment is controlled to ensure the coverage of the diaphragm and the negative electrode, and finally packaged. If you need to stack several layers of pole pieces, you can also weld the pole ears after stacking, and the same pole pieces can share one pole ear; the lower right corner of the picture uses a continuous diaphragm and stacks in a Z-shaped manner.